- Health and safety at work is therefore aimed at creating conditions, capabilities, and habits that enable the worker and his/her organization to carry out their work efficiently and in a way that avoids events which could cause them harm (Garcia-Herrero et al., 2012). It is clear that safe working conditions have an effect on the.

- Download Workplace Management Ohno Pdf Editor. Kelly Nocero Lost 100 Pounds: Your personal information and card details are 100% secure. Born in Dalian, in eastern China, he joined Toyota Automatic Loom Works between the wars. This was the first business of the Toyoda family until it was sold to a British company, Platt Brothers, and the family.

- Health and safety at work is therefore aimed at creating conditions, capabilities, and habits that enable the worker and his/her organization to carry out their work efficiently and in a way that avoids events which could cause them harm (Garcia-Herrero et al., 2012). It is clear that safe working conditions have an effect on the.

Concept in management that will work in any type of business.” Taiichi Ohno. Kaizen Equipment People Material Standard Work Takt Time Production Standard Work-in-Process One Piece Flow Pull Production Operational Availablity JIDOKA (Autonomation).Automation with the human touch.

Workplace Management

By Taiichi Ohno

Amazon Summary

This unique volume delivers a clear, concise overview of the Toyota Production System and kaizen in the very words of the architect of both of these movements, Taiichi Ohno. Filled with insightful new commentary from global quality visionaries, Taiichi Ohno’s Workplace Management is a classic that shows how Toyota managers were taught to think.

Reader Summary

The superior person knows how to adapt. The superior man does not fear change.

– Confucius

Taiichi Ohno offers distinct and elegant advice on a number of questions and topics concerned with the Toyota Production System. Ohno reflects on thirty-six topics that explain how best to manage a workplace. I will pluck out my favorite concepts and discuss their merits here. This is not a comprehensive book review, but only a summary of my takeaways from the book.

The three areas I chose to address are:

- To get to the Lean we know today, it was necessary to look at the problem of work in a contrary way from the prevailing wisdom. Ohno calls it “postconventional wisdom”.

- Words have meaning. People use terms and concepts incorrectly, which cause waste and inefficiency in the workplace.

- Kaizen, costs, and standards. I summarize Ohno’s main points on these topics.

On the Contrary

Taiichi Ohno makes it clear in the Preface that the Toyota Production System can be summed up in a single phrase:

Make only what you need, in the quantities you need, when you need it.1

In this quote, Taiichi Ohno refers to the most basic tenet that turned traditional production processes on its head. The typical way of doing things called for parts to be transported to later processes as soon as they were made. This process caused a disconnect with customer demand. Ohno observed how easy it was for departments to feel good about the multitude of parts they could produce in a month. However, only Ohno seemed to notice that no cars were completed in that time period. Why? Mass production always rewarded those who produced the most. There was no sense that each department’s output must form an integrated set that is consumed by the customer. To correct this, each department must operate in unison with the set. Atypically, some departments must become idle if their contribution to the set is not needed at the moment. This became the crux of the post-conventional wisdom that Ohno required to change the system. He even makes a comment about himself to explain why he was able to create this type of thinking:

Nevertheless, I insisted on talking about “postconventional wisom,” perhaps because I have a contrary streak in me and tend to look at things backwards.2

Looking at things backwards creates a historical moment. Taiichi Ohno created just-in-time production by reversing the system from push to pull.

A process that needs a part goes to an earlier process to get it. It’s that easy. No trouble at all.3

My Own Experience

I see this example in the IT industry all the time. The server department pats themselves on the back for creating X servers per month. The web services department glows when they set up Y number of web environments. However, when the customer receives their environment, they can’t log into it because nobody thought about giving them access. There is a very large piece missing in both examples. Nobody (or somebody) is not noticing the true goal of the production process, to hand the keys to someone so that they can consume their product.

Words Have Meaning

Ohno likes to point out the importance of correct terminology. Through his experience, he has seen other organizations look at work the wrong way out of habit. The corrections he makes are central to the Lean mentality, yet hamper organizations everywhere.

Motion vs. Work

Ohno makes several points that begin to explain the concept of value vs. waste. He picks apart typical ways of referring to activities in the workplace. Two quotes illustrate his point. They are:

- Don’t manage speed or motion, manage work.4

- If people are sweeping while waiting for parts, that’s not working. Everyone confuses motion with work.5

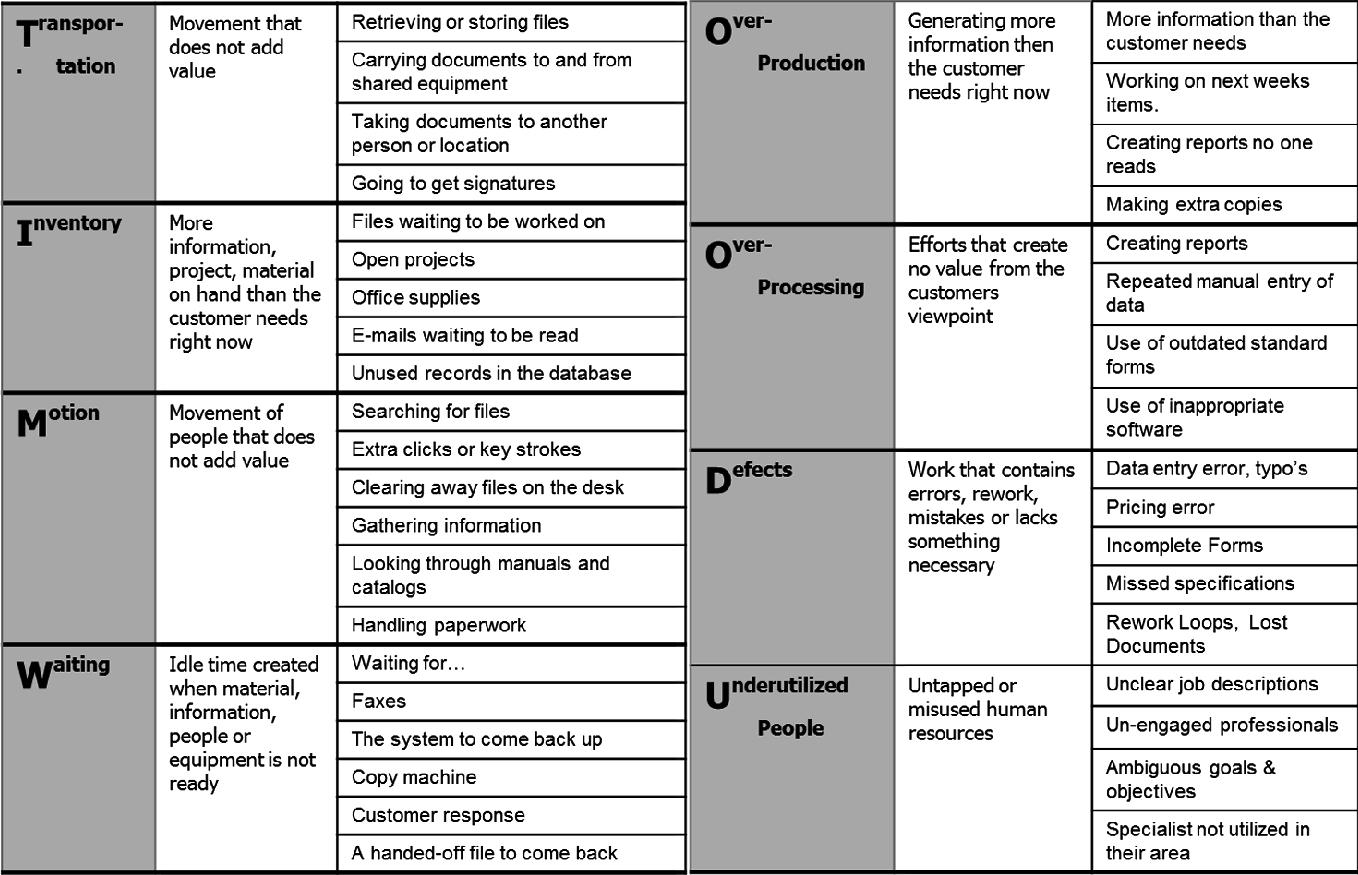

Ohno accuses the traditional manufacturing industry of looking at work the wrong way. He insists that you must look one level deeper at work activities because only some of the time spent making a product is actually… making the product. Just because people are moving all the time, racing to and fro, cleaning, sweeping, monitoring, attending meetings, or handing off work to the next step, it doesn’t mean that they must surrender to this fate. These “extras” are not work. If it isn’t work, then it is taking too long or costing too much to produce the output. I’m not a historian of Lean, but since this book was written in 1982, this could easily be a precursor to the Lean concepts of value stream and the two types of muda:

- Type I – non-value added activity, necessary for end customer.

- Type II : non-value added activity, unnecessary for end customer. The aim is to eliminate this type of wastage.

As a result, Ohno illustrates that the only activity that matters is the value-added activity that creates the product. That’s the real work.

Organization and Orderliness6

Ohno goes down to the basic structure of the Japanese language to define words in the right way. He defines organization as anything that “involves disposing of things you don’t need.” Orderliness means “always having access to things you need.” Using these two words together create an optimized working environment. Strip away the bad and keep only the good. If you must move everything out of the way to get what you need, then you have neither organization or orderliness. That is why keeping a clean shop floor has been such an important principle for Lean.

Processing Time and Processing Worker Hours7

Here, Ohno wants to parse the total time it takes to create a part. In his example, a part may take five minutes to complete. However, only one minute of the effort requires a person to mount a part on a machine and remove the part when it is finished. The remaining four minutes is watching the machine process the part. Since this four minutes is waste, then the remedy is to assign the person to more than one machine. This sounds simple, but processes and production efforts across the world still calculate their time and labor estimates on the full five minutes. Likewise, specialists still cling to their “one machine” mindset and make it difficult to contribute more cross-functionally. Once again, Ohno tells us to look deeper.

If you take this example and bring it to my own work world, I have seen, time and time again, situations where something takes 5 days to deliver but requires only 20 minutes of actual work. It is extremely important to make people aware of this. Even when you do that, it still may fall on deaf ears. In these situations, you need to push for a single-piece flow experiment. Pick the items you want to produce in one day and align your resources so that every single step occurs in one day instead of being handed off to a queue where it may not be picked up for two days. Processing time should never be held hostage to processing worker hours.

Rate of Operability vs. Rate of Operation8

Ohno indicates how many get the two terms above backwards. Rate of operability is defined as how much a machine is able to do work. Related, but not the same, is the rate of operation, which varies with the demand of work. Ohno insists that the former must be maximized but the latter should not. Oftentimes, production facilities do the opposite. They will let a machine die or neglect maintenance so that it functions below par, yet push active machines to produce full time without regard to customer demand. Ohno prefers that you maximize the usability of whatever machines you have. Make them ready at all times so that they are ready for a spike in demand. Otherwise, leave them offline but fully maintained. If there is no demand, then the machines should not operate. He also warns against thinking that productivity increases the more a machine produces. Overproduction, in Ohno’s mind, is one of the worst enemies of productivity. It is always best to keep machines ready to produce only the amount needed and no more.

Kaizen

Ohno explains the importance of improvement that makes the most of what you already have. Specifically, he states that kaizen is an operational improvement that comes up with better methods of using existing equipment. It is most important to think of new work methods before making new tools or buying equipment. In fact, there is no point in buying new equipment if a team doesn’t know how to do general improvements first.

Ohno elaborates further by establishing an order to pursue improvement. First, you must improve your operations. Again, make the current operation more productive and make sure that there is an improvement in quality. Do not bring in new machines yet. If you do, people become slaves to the machines. People with no capacity for improving operations are a problem because they like to buy new machines all the time.9

Second, you must improve your equipment. This is a close relative of the first step, operations. What Ohno clarifies here is that the people on the shop floor must possess the skills to tinker and improve the machines. If they only solve their problems by buying new machines and using them per vendor specification, they will never squeeze out the local and custom level of capability and creativity that enhances productivity.10

Third, and last, as emphasized by Ohno is process improvement. This effort creates the flow for how machines are used and how quality is produced. Ohno reinforces his point that no improvement is worthwhile unless the people using the process understand it and can alter it based on their knowledge on the ground. People on the front lines own the process. They cannot work in a daze because management, technicians, or “experts” decided on the procedures. There also cannot be reliance upon one big change to fix all ills. Ohno makes it clear that kaizen is an ongoing activity made up of many small improvements diagnosed and implemented by the people doing the process. Having a culture where the front line people do this every day is the optimal method for increasing productivity and quality.11

Only the Workplace Can Cut Costs

As an extension of the ongoing kaizen, companies must embed cost reduction into all their activities. The ultimate measure of success for a manager is to do the same work with fewer people than before. That is one reason why Ohno holds so tightly to the principle of multi-machine supervision. So too, costs will also come down to the extent that defects are reduced.12

Cost reduction must happen all the time. You cannot wait until times get bad to start your cost reduction efforts. It takes a long time to get results, so you must remain vigilant even when it seems easy to coast. To have this kind of discipline, a company needs people to nag13 in order to stay committed to reducing cost.14

Lastly, Ohno makes a special note that only the workplace can cut costs. Accounting cannot.15 No matter what quota or targets are set by Accounting, the workplace must be willing to do the work. The workplace therefore has an obligation to take ownership of that responsibility. They must be fanatics about cost reduction as though cost-cutting were impossible outside the workplace. So much so, that tenacity becomes the differentiating factor for how successful cost reduction becomes. This cannot be executed by Accounting; only the shop floor can achieve it.16

Standards

Creating success from Ohno’s advice is a constant balancing act, especially when it comes to standards. Standards must always exist, but they always must change. In order to improve, you must be able to improve from the existing standard. As Ohno states, “Standards are a kind of baseline for improvement” because standards can never be perfect.<sup17< This can be unsettling to some who want more certainty and consistency. However, Ohno warns that, “trying to get the perfect method from the first will quash the desire to improve.” Consequently, people in the workplace need to accept both standards and change as two sides of the same coin. You can’t have one without the other.

Second, Ohno spends some time discussing “chosen procedures”. There is a good side and a bad side to this term. The bad side says that chosen procedures are chosen by management or outside the immediate workplace. People can hold themselves hostage to the idea that they can’t change or improve the system. This makes it look like coercion is involved to make workers follow procedures. (maybe it’s true!) Ohno prefers the good side, which says the frontline works choose the procedures. The worker himself has the authority to choose. There is no question of anything like correction when an individual adheres to procedures chosen by him or herself.18

Lastly, Ohno tells us how to choose the right standard. In his experience, most test a process multiple times and take the average duration as the standard. Ohno disagrees and says that you should adopt the shortest time. Why? Because the shortest time shows how everything went right. It has the least amount of waste. This should be emulated, not averaged away as a statistical outlier. Once you choose the shortest standard, then you can focus on eliminating the waste that infected all the others in the sample.

Epilogue

This is the second book I’ve ready by Taiichi Ohno. (See my review of The Toyota Production Systemhere) I love Ohno’s style. He makes everything sound so simple and clear. You get a sense, quickly, that he is an authority on the topics he discusses. Ohno can write about a concept in a very short amount of words, yet they explain everything. His writing style is as efficient as his improvement systems.

I chose to read Ohno’s books to ground myself in the origins of Lean. I’m glad I did it since it gives me perspective on how the current processes formed. It gives me the original “5 Whys” perhaps. Since he is the standard, I can use it as a baseline for everything else.

I recommend Workplace Management highly. It is a short read packed with a lot of great stuff. If I had to choose, I suppose I think that The Toyota Production System was better. However, I feel like I get a more comprehensive understanding of the man who did so much to shape the future of manufacturing and improvement.

1 Taiichi Ohno, Workplace Management, (Cambridge, MA.: Productivity Press, 1988), p. ix.

2 Ibid., p. 78

3 Ibid., p. 78

4 Ibid., p. 107

5 Ibid., can’t find page

6 Ibid., p. 117

7 Ibid., p. 126

8 Ibid., p. 128

9 Ibid., p. 123

10 Ibid., p. 124

11 Ibid., p. 125

12 Ibid., p. 92

13 Ibid., p. 120

14 Ibid., p. 143

15 Ibid., p. 145

16 Ibid., p. 147

17 Ibid., p. 148

18 Ibid., p. 148

sup>

Taiichi Ohnos Workplace Management

Author :Taiichi OhnoISBN :9780071808026

Genre :Business & Economics

File Size : 68.68 MB

Format :PDF, ePub, Docs

Download :478

Workplace Management Ohno Pdf Files Google Drive

Read :734

COMMEMORATING THE 100th BIRTHDAY OF TAIICHI OHNO Businesses worldwide are successfully implementing the Toyota Production System to speed up processes, reduce waste, improve quality, and cut costs. While there is widespread adoption of TPS, there is still much to be learned about its fundamental principles. This unique volume delivers a clear, concise overview of the Toyota Production System and kaizen in the very words of the architect of both of these movements, Taiicho Ohno, published to mark what would have been his 100th birthday. Filled with insightful new commentary from global quality visionaries, Taiichi Ohno’s Workplace Management is a classic that shows how Toyota managers were taught to think. Based on a series of interviews with Ohno himself, this timeless work is a tribute to his genius and to the core values that have made, and continue to make, Toyota one of the most successful manufacturers in the world. 'Whatever name you may give our system, there are parts of it that are so far removed from generally accepted ideas (common sense) that if you do it only half way, it can actually make things worse.' 'If you are going to do TPS you must do it all the way. You also need to change the way you think. You need to change how you look at things.' -- Taiichi Ohno 'This book brings to us Taiichi Ohno's philosophy of workplace management--the thinking behind the Toyota Production System. I personally get a thrill down my spine to read these thoughts in Ohno’s own words.' -- Dr. Jeffrey Liker, Director, Japan Technology Management Program, University of Michigan, and Author, The Toyota Way Based on a series of interviews with Taiicho Ohno, this unique volume delivers a clear, concise overview of the Toyota Production System and kaizen in the very words of the architect of both of these movements, published to mark what would have been his 100th birthday. INCLUDES INSIGHTFUL NEW COMMENTARY FROM: Fujio Cho, Chairman of Toyota Corporation Masaaki Imai, Founder of the Kaizen Institute Dr. Jeffrey Liker, Director, Japan Technology Management Program, University of Michigan, and author John Shook, Chairman and CEO of the Lean Enterprise Institute Bob Emiliani, Professor, School of Engineering and Technology, Connecticut State University Jon Miller, CEO of the Kaizen Institute

Taiichi Ohno S Workplace Management

Author :Taiichi ŌnoISBN :0978638751

Genre :Automobile industry and trade

File Size : 39.12 MB

Format :PDF, ePub, Docs

Download :240

Read :951

Workplace Management

Author :Taiichi OhnoISBN :0318326698

Genre :

File Size : 77.37 MB

Format :PDF, Docs

Download :446

Read :1084

The Leader S Guide To Radical Management

Author :Stephen DenningISBN :0470651369

Genre :Business & Economics

File Size : 24.62 MB

Format :

Workplace Management Ohno Pdf Files 2017

PDF, MobiDownload :447

Read :526

A radical new management model for twenty-first century leaders Organizations today face a crisis. The crisis is of long standing and its signs are widespread. Most proposals for improving management address one element of the crisis at the expense of the others. The principles described by award-winning author Stephen Denning simultaneously inspire high productivity, continuous innovation, deep job satisfaction and client delight. Denning puts forward a fundamentally different approach to management, with seven inter-locking principles of continuous innovation: focusing the entire organization on delighting clients; working in self-organizing teams; operating in client-driven iterations; delivering value to clients with each iteration; fostering radical transparency; nurturing continuous self-improvement and communicating interactively. In sum, the principles comprise a new mental model of management. Author outlines the basic seven principles of continuous innovation The book describes more than seventy supporting practices Denning offers a rethinking of management from first principles This book is written by the author of The Secret Language of Leadership—a Financial Times Selection in Best Books of 2007.

The Lean Farm

Author :Ben HartmanISBN :9781603585927

Genre :Agriculture

File Size : 52.75 MB

Format :PDF, ePub

Download :443

Read :1110

A practical, systems-based approach for a more sustainable farming operation To many people today, using the words “factory” and “farm” in the same sentence is nothing short of sacrilege. In many cases, though, the same sound business practices apply whether you are producing cars or carrots. Author Ben Hartman and other young farmers are increasingly finding that incorporating the best new ideas from business into their farming can drastically cut their wastes and increase their profits, making their farms more environmentally and economically sustainable. By explaining the lean system for identifying and eliminating waste and introducing efficiency in every aspect of the farm operation, The Lean Farm makes the case that small-scale farming can be an attractive career option for young people who are interested in growing food for their community. Working smarter, not harder, also prevents the kind of burnout that start-up farmers often encounter in the face of long, hard, backbreaking labor. Lean principles grew out of the Japanese automotive industry, but they are now being followed on progressive farms around the world. Using examples from his own family’s one-acre community-supported farm in Indiana, Hartman clearly instructs other small farmers in how to incorporate lean practices in each step of their production chain, from starting a farm and harvesting crops to training employees and selling goods. While the intended audience for this book is small-scale farmers who are part of the growing local food movement, Hartman’s prescriptions for high-value, low-cost production apply to farms and businesses of almost any size or scale that hope to harness the power of lean in their production processes.

Quality Management In Engineering

Author :Jong S. LimISBN :9781000449082

Genre :Technology & Engineering

File Size : 30.69 MB

Format :PDF, ePub

Download :768

Read :511

This book introduces fundamental, advanced, and future-oriented scientific quality management methods for the engineering and manufacturing industries. It presents new knowledge and experiences in the manufacturing industry with real world case studies. It introduces Quality 4.0 with Industry 4.0, including quality engineering tools for software quality and offers lean quality management methods for lean manufacturing. It also bridges the gap between quality management and quality engineering, and offers a scientific methodology for problem solving and prevention. The methods, techniques, templates, and processes introduced in this book can be utilized in various areas in industry, from product engineering to manufacturing and shop floor management. This book will be of interest to manufacturing industry leaders and managers, who do not require in-depth engineering knowledge. It will also be helpful to engineers in design and suppliers in management and manufacturing, all who have daily concerns with project and quality management. Students in business and engineering programs may also find this book useful as they prepare for careers in the engineering and manufacturing industries. Presents new knowledge and experiences in the manufacturing industry with real world case studies Introduces quality engineering methods for software development Introduces Quality 4.0 with Industry 4.0 Offers lean quality management methods for lean manufacturing Bridges the gap between quality management methods and quality engineering Provides scientific methodology for product planning, problem solving and prevention management Includes forms, templates, and tools that can be used conveniently in the field

Improve

Author :George EllisISBN :9780128095195

Genre :Technology & Engineering

File Size : 77.42 MB

Format :PDF, ePub, Mobi

Download :422

Read :754

Improve: The Next Generation of Continuous Improvement for Knowledge Work presents lean thinking for professionals, those who Peter Drucker called knowledge workers. It translates the brilliant insights from Toyota's factory floor to the desktops of engineers, marketers, attorneys, accountants, doctors, managers, and all those who 'think for a living.' The Toyota Production System (TPS) was born a century ago to an almost unknown car maker who today is credited with starting the third wave of the Industrial Revolution. TPS principles, better known as lean thinking or continuous improvement, are simple: increase customer value, cut hidden waste, experiment to learn, and respect others. As simple as they are, they are difficult to apply to the professions, probably because of the misconception that knowledge work is wholly non-repetitive. But much of our everyday work does repeat, and in great volume: approvals, problem-solving, project management, hiring, and prioritization are places where huge waste hides. Eliminate waste and you delight customers and clients, increase financial performance, and grow professional job satisfaction, because less waste means more success and more time for expertise and creativity. This book is a valuable resource for leaders of professional teams who want to improve productivity, quality, and engagement in their organizations. Experience the proven benefits of continuous improvement 40%-70% increase in productivity from professionals and experts li”85% projects on-time/liliReduce lead time by 50%-90%/liliEngagement up and voluntary severance cut 50% Dozens of simple visual tools that anyone can implement immediately in their existing framework All tools and techniques applicable to both face-to-face and virtual meetings Easy-to-understand approach: 'simplify, engage, experiment” Presented with deep respect for the experts; no 'check the box” thinking or overused analogies to the factory floor

Business

Author :布卢姆斯伯里出版公司ISBN :7800736598

Genre :Business

File Size : 42.90 MB

Format :PDF, ePub, Docs

Download :297

Read :1016

责任者取自版权页。

Production And Operations Management

Author :CharyISBN :0070091536

Genre :Materials management

File Size : 20.86 MB

Format :PDF, ePub, Docs

Format :PDF, ePub, Docs Download :150

Read :1014

Customers For Life

Author :Carl SewellISBN :0307567311

Genre :Business & Economics

File Size : 89.19 MB

Format :PDF, Docs

Download :192

Read :539

In this completely revised and updated edition of the customer service classic, Carl Sewell enhances his time-tested advice with fresh ideas and new examples and explains how the groundbreaking “Ten Commandments of Customer Service” apply to today’s world. Drawing on his incredible success in transforming his Dallas Cadillac dealership into the second largest in America, Carl Sewell revealed the secret of getting customers to return again and again in the original Customers for Life. A lively, down-to-earth narrative, it set the standard for customer service excellence and became a perennial bestseller. Building on that solid foundation, this expanded edition features five completely new chapters, as well as significant additions to the original material, based on the lessons Sewell has learned over the last ten years. Sewell focuses on the expectations and demands of contemporary consumers and employees, showing that businesses can remain committed to quality service in the fast-paced new millennium by sticking to his time-proven approach: Figure out what customers want and make sure they get it. His “Ten Commandants” provide the essential guidelines, including: • Underpromise, overdeliver: Never disappoint your customers by charging them more than they planned. Always beat your estimate or throw in an extra service free of charge. • No complaints? Something’s wrong: If you never ask your customers what else they want, how are you going to give it to them? • Measure everything: Telling your employees to do their best won’t work if you don’t know how they can improve.

Creating A Kaizen Culture Align The Organization Achieve Breakthrough Results And Sustain The Gains

Author :Jon MillerISBN :9780071826860

Genre :Business & Economics

File Size : 83.46 MB

Format :PDF, Docs

Workplace Management Ohno Pdf Files Download

Download :498

Read :447

FOSTER AND SUSTAIN A KAIZEN CULTURE IN YOUR ORGANIZATION WINNER of the 2015 Shingo Research and Professional Publication Award! FOREWORD BY JOHN TOUSSANT, CEO OF THEDACARE Transforming a culture is far more about emotional growth than technical maturity. Co-written by leaders at the Kaizen Institute, Creating a Kaizen Culture explains how to enable an adaptive, excellent, and sustainable organization by leveraging core kaizen values and the behaviors they generate. The proven methods presented in this book will dramatically increase your chances of success in implementing a kaizen culture by closing the biggest gaps in the correct understanding of: WHAT KAIZEN CULTURE IS AND WHY WE NEED IT HOW EVERYONE, EVERYWHERE CAN PRACTICE KAIZEN EVERY DAY THE LEADER'S ROLE IN TURNING KAIZEN CULTURE INTO COMPETITIVE ADVANTAGE Based on more than 50 years of combined experience from experts who have successfully used kaizen to lead real transformation in a wide variety of industries, Creating a Kaizen Culture reveals how to propel rapid and sustainable performance improvement. It provides a detailed and illustrated road map to organized kaizen implementation through kaizen events. Real-world examples demonstrate kaizen culture in action at Toyota, Zappos, Wiremold, and many other companies. Featuring valuable insights from Kaizen Institute leaders, this practical resource covers: WHY WE NEED A KAIZEN CULTURE THE TRUE MEANING OF KAIZEN THE ORIGIN OF THE KAIZEN EVENT KAIZEN AS A STRATEGY IN PRACTICE DAILY KAIZEN SUSTAINING A KAIZEN CULTURE ORGANIZATIONAL READINESS FOR KAIZEN TRANSFORMATION FACING UP TO THE CULTURE MONSTER CASE STUDIES OF REAL-WORLD KAIZEN IMPLEMENTATION IN ORGANIZATIONS OF VARIOUS SIZES AND INDUSTRIES

Humam Resource Management

Author :ISBN :8185790868

Genre :

File Size : 44.52 MB

Format :PDF, Kindle

Download :534

Read :1042

Operations Management For Dummies

Author :Mary Ann AndersonISBN :9781118551073

Genre :Business & Economics

File Size : 69.80 MB

Format :PDF, Mobi

Workplace Management Ohno Pdf Files Free

Download :448Read :1033

Score your highest in Operations Management Operations management is an important skill for current and aspiring business leaders to develop and master. It deals with the design and management of products, processes, services, and supply chains. Operations management is a growing field and a required course for most undergraduate business majors and MBA candidates. Now, Operations Management For Dummies serves as an extremely resourceful aid for this difficult subject. Tracks to a typical course in operations management or operations strategy, and covers topics such as evaluating and measuring existing systems' performance and efficiency, materials management and product development, using tools like Six Sigma and Lean production, designing new, improved processes, and defining, planning, and controlling costs of projects. Clearly organizes and explains complex topics Serves as an supplement to your Operations Management textbooks Helps you score your highest in your Operations Management course Whether your aim is to earn an undergraduate degree in business or an MBA, Operations Management For Dummies is indispensable supplemental reading for your operations management course.

Management Lessons From Taiichi Ohno What Every Leader Can Learn From The Man Who Invented The Toyota Production System

Author :Takehiko HaradaISBN :9780071849746

Genre :Business & Economics

File Size : 51.13 MB

Format :PDF, Kindle

Download :416

Read :375

The 15 most powerful practices of the legendary Taiichi Ohno you can use to drive breakthrough productivity improvements in your company Having spent 40 years working at the side of Taichii Ohno at Toyota, Takehiko Harada recounts his experiences transforming operations as we know them. In Management Lessons from Taichii Ohno, Harada explains, “Good Kaizen makes an environment where work is meaningful. To create a workplace like this, it is crucial to train people in the management of a lean organization.” The book provides managers and executives with the tools they need to implement TPS/Lean within their organization.

The Essentials Of The New Workplace

Author :David HolmanISBN :9780470022160

Genre :Psychology

File Size : 50.7 MB

Format :PDF

Download :969

Read :344

The original hardback edition of The New Workplace examined modern business terms such as total quality management, just-in-time production, e-business, lean manufacturing and teleworking. It explored what these terms really mean and what effect they have in practice - especially their impact on productivity and performance and their social and psychological consequences. This paperback is a shorter, revised version of the original book. It will focus on working practices, especially technology orientated ones, which are the most relevant and innovative for consultants.

Kanban Just In Time At Toyota

Author :JapanManagementAssociationISBN :9781351436182

Genre :Business & Economics

File Size : 39.9 MB

Format :

PDF

PDF Download :396

Read :334

Toyota's world-renowned success proves that just-in-time (JIT) makes other manufacturing practices obsolete. This simple but powerful book is based on the seminars given by Taiichi Ohno and other senior production staff to introduce Toyota's own supplier companies to JIT. It teaches the philosophy and implementation of what many call the most efficient production system in the world. Provides a clear structure for an introductory JIT training program. Explains every aspect of the JIT system, including how to set it up and how to refine it once it's in place. Shows how to use a simple visual system to control the production process. Every day more American companies are learning that JIT works outside Japan. Now you can get started with this step-by-step book which guides you through the implementation process. Every engineer, manager, supervisor, and worker should read this book to get the clearest, simplest, and most complete introduction to JIT available in English. Results at American companies after reading this book: Lead-time on one product was reduced from 12 weeks to 4 days. Setup time on a large blanking press was reduced from eight hours to one minute and four seconds. Work-in-process has been reduced 50 percent plant-wide. Factory floor space was opened up 30 to 40 percent in every on of their plants.

The Lean Expert

Author :Joseph NiederstadtISBN :9781482253665

Genre :Business & Economics

File Size : 57.8 MB

Format :PDF, Kindle

Download :577

Read :

The Lean Expert: Educating and Elevating Lean Practitioners Throughout Your Organization outlines a method that can help organizations engage associates and empower them to achieve 'expert status' in the nine core principles of Lean. By implementing the Lean Discipline Expert process detailed in the book, companies will demonstrate to their associates that they believe they are the organization’s greatest assets, while empowering them to make lasting improvements to the organization. The book provides a robust and proven process for creating a Lean culture. It outlines a method, with defined steps, for the development of Lean Discipline Resource People that will help associates achieve 'expert status' in the core Lean principles of 5S–Visual Management, Value Stream Mapping, Standard Work, Total Productive Maintenance, Quick Changeover, Error Proofing, Process Problem Solving, Material Management, and Continuous Improvement. You will be able develop Lean strategies, create a Master Schedule, initiate activities for supporting goals and objectives, and complete a Train-the-Trainer class as well as achieve facilitation skills to teach, communicate, guide, and lead Lean overview training as well as comprehensive subject-matter training. In addition, you will understand how the Lean Discipline Expert process can help to support associate involvement at all levels and learn where and how the nine principles overlap and interact. By engaging and empowering various levels of associates throughout the organization, you will provide strength and ownership for your business and, most importantly, your associates. The book includes access to additional resources on the book’s page at www.crcpress.com. It includes a tracking mechanism for monitoring candidate progress, facilitation feedback forms, LDE checklists, and certificates of accomplishment you can use to acknowledge associates that achieve Lean Discipline Expert status.

Implementing A Lean Management System

Author :Thomas L. JacksonISBN :1563270854

Genre :Business & Economics

File Size : 52.19 MB

Format :PDF, Kindle

Download :889

Read :1294

Does your company think and act ahead of technological change, ahead of the customer, and ahead of the competition? Thinking strategically requires a company to face these questions with a clear future image of itself. Implementing a Lean Management System lays out a comprehensive management system for aligning the firm's vision of the future with market realities. Based on hoshin management, the Japanese strategic planning method used by top managers for driving TQM throughout an organization, Lean Management is about deploying vision, strategy, and policy at all levels of daily activity. It is an eminently practical methodology emerging out of the implementation of continuous improvement methods and employee involvement. The key tools in the text build on the knowledge of the worker, multi-tasking, and an understanding of the role and responsibilities of the new lean manufacturer.

Re Engineering At Work

Author :Michael LohISBN :0566079410

Genre :Business & Economics

File Size : 54.75 MB

Format :PDF, ePub, Mobi

Download :401

Read :191

Business process re-engineering has been hailed as the answer to the challenges faced by business in the late 1990s, yet many re-engineering programmes have fallen short of expectations, or have failed altogether. Several years on, where is it all going now? What benefits does it have to offer today?

Dominant Divisions Of Labor Models Of Production That Have Transformed The World Of Work

Author :T. JanoskiISBN :9781137370235

Genre :Social Science

File Size : 87.11 MB

Format :PDF, ePub, Mobi

Download :407

Read :155

The past century of labor was definitively captured by theories like Fordism and Taylorism, or scientific managment, but how do we make sense of global production today? This short book takes a panoramic view of the candidates for the most succinct theory of the 21st century division of labor, including post-Fordism, flexible accumulation, McDonaldization, Waltonism, Nikeification, Gatesism and Siliconism, shareholder value, and lean production and Toyotism. Authors Thomas Janoski and Darina Lepadatu argue that lean production in a somewhat expanded version presents three variations: Toyotism (the strongest form), Nikeification (a moderate form with off-shored plants lacking teamwork) and Waltonism (the merchandising form that presses for off-shoring). While all three share strong elements of 'just in time' (JIT) production and supply chain management, they differ in how teamwork and long-term philosophies are valued. This critical review of dominant established theories serves to inform subsequent research on the contemporary international division of labor.